Solidworks model of motor-jar interface. The chamfered corners allow the blender to accept standard Blendtec jars, while being the only interface that works with Nitro system.

Reverse side

Before sending part files to mold makers, a draft analysis must be performed to determine if the part can be molded.

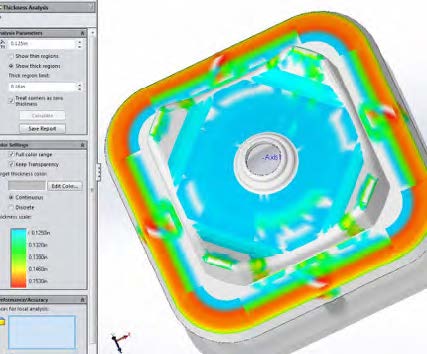

Thickness analysis identifies thin sections that could be weak spots in the part, or thick sections that cause sinks and other aesthetic imperfections.

Initial injection molded samples. I then performed a First Article Inspection to verify the mold and process.

gLike