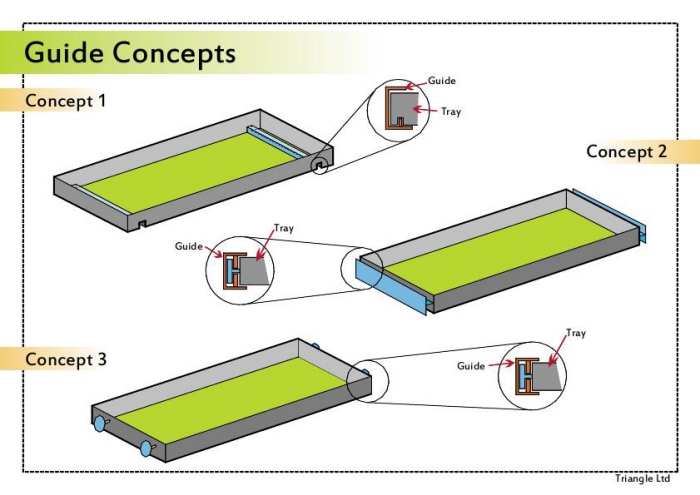

Concept ideas for a raised scaffolding walkway. Presented to Hampshire County Council.

View PDF

View PDF

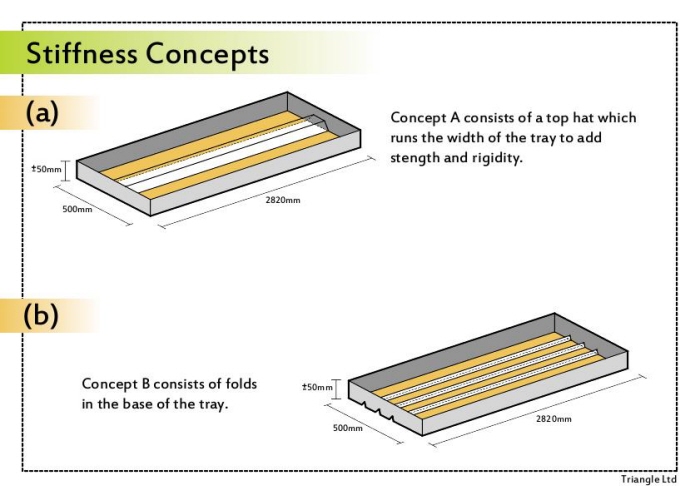

Stiffness concepts presented to the council.

View PDF

View PDF

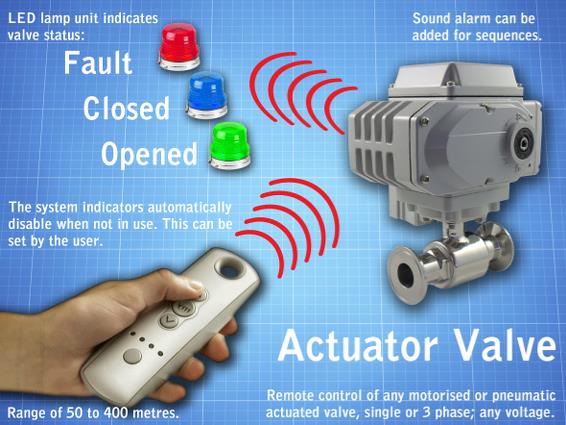

A board I designed to advertise the range of projects Triangle Ltd undertake.

View PDF

View PDF

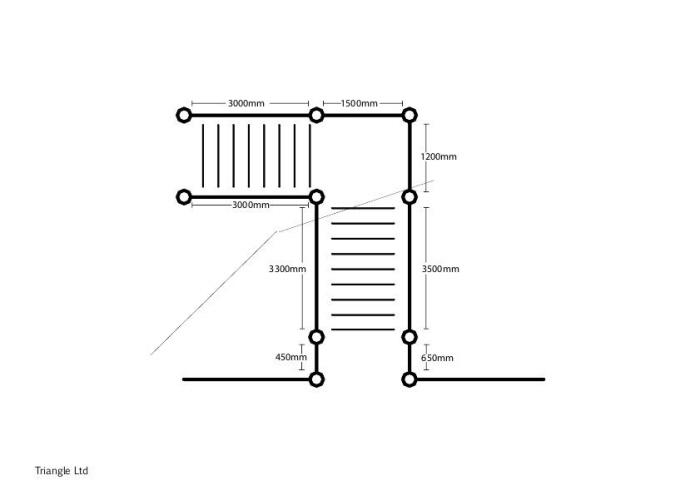

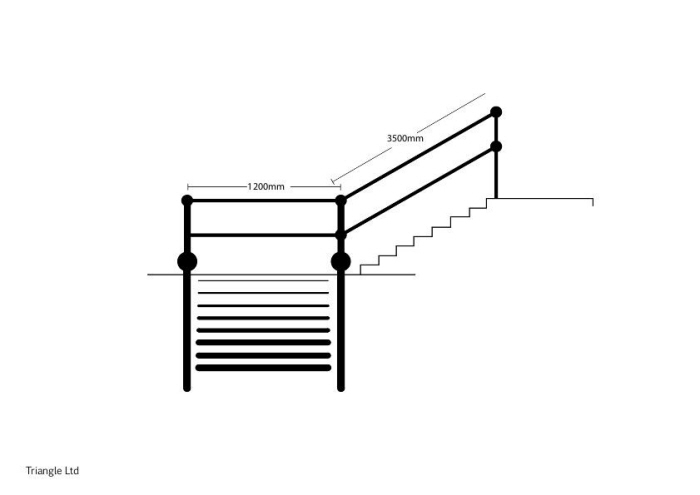

A top down view of railings including measurements.

View PDF

View PDF

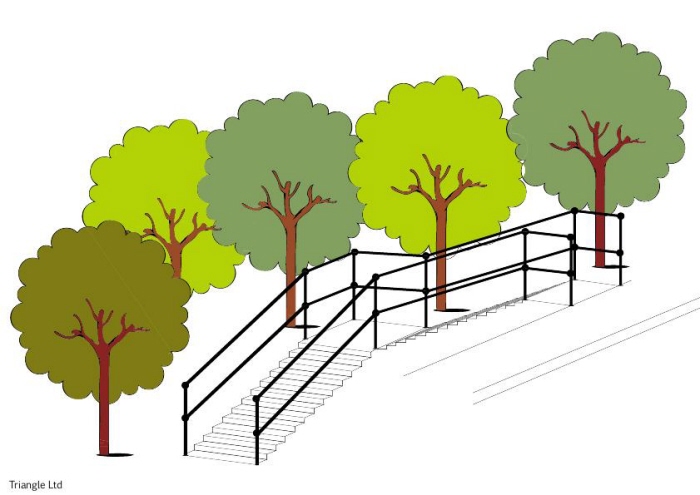

A side on view of railings which we designed for a set of stairs in the New Forest.

View PDF

View PDF

What the railings would look like from the street.

View PDF

View PDF

I learnt to use the MIG welder in the Triangle Ltd workshop.

An example of my welding!

Over 75 struts go into one cattle grid. All struts have to be welded in a jig, drilled, milled and then galvanised before they are ready to be installed.

Some galvanised struts in place. The modular system means faults can be replaced without the whole grid being dug out.

A hedgehog escape ramp!

The finished grid all shiny and new!

A railing we installed on the South Downs.

gLike