This was a two man group Project : Nate Zellmer, and Lucas Van Dyke

Project Charter: To update the mechanical performance of the upper-limb prosthesis, or prosthetic hook. Add functionality, improve aesthetics, and increase usability.

The prosthetic hook has not been majorly changed since 1912, and comes in two major varieties. Voluntary Open or Voluntary close. Which means by shrugging your shoulder you can control the hook by either closing it or opening it depending on its resting position.

To efficiently and smoothly use a body-powered prosthesis, the device must be mechanically efficient and require a low activation force. A previous study on voluntary closing (VC) devices showed that nearly all tested devices were inefficient and required high activation forces that users might find uncomfortable.

Marine Captain Jonathan Kuniholm has a PhD in biomedical engineering at Duke University and has master's degrees in mechanical engineering and industrial design from North Carolina State University. He has worked in the research and development of tools for robotic cardiac surgery for Cardiovations, a Johnson & Johnson company. He is an officer in the Marine Corps Reserve. And has served with distinction for 9 years.

Kuniholm was sent to Iraq in 2004. On New Year’s Day 2005, Iraqi insurgents ambushed his patrol. They remotely detonated a device packed with shrapnel and explosives, and then started firing their weapons as the platoon took cover and returned fire. “I was wounded in the initial explosion, and my right arm was later amputated below the elbow,” Kuniholm says.

Jon Presented the project to Nate and I, and showed us the limitations his new hand was experiencing. As we asked him many questions, we were able to use his Design and Engineering knowledge to our benefit.

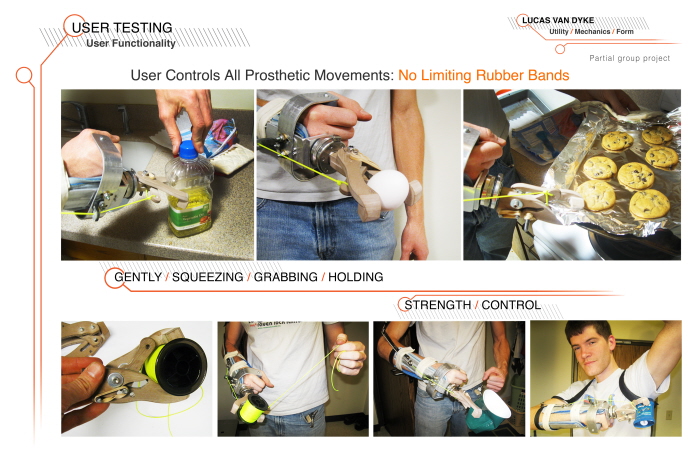

Nate and I used a prosthetic hook that could be worn on our arm and found there were positive and negative functions about the current design. The multiple limitations included: very difficult to push on anything cylindrical or round like a shopping cart or door handles. Also, due to the rounded nature of the hook, holding down a piece of paper was hard, for example the hook only acted as a point for the receipt to pivot around while trying to sign it. It was also very difficult to squeeze anything with a particular strength, To hold an egg lightly, the user would apply negative force against the rubber band but not too much force or it would release. And there is no ability to grip beyond the grip provided by the rubber bands. The more rubber bands on the hook meant the more force the user had to pull against every time they wanted to use it but the more gripping power the user would have, and visa versa.

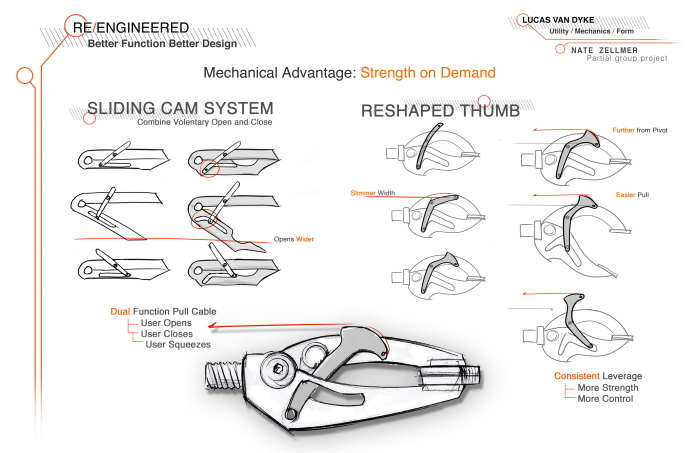

Nate and I engineered linkage that allows the Prosthesis to act in both a Voluntary open and Voluntary close with one single pull of the shoulder. This provided the best of both worlds for the user, able to "feel" the grip they were delivering and also feel the resistance on the cable. The rounded nob in the thumb provided a smooth transition and constant pull pressure throughout the draw of the slider. The User would no longer need to struggle against unnecessary rubber bands, but would be able to squeeze with strength upon demand. The hook would return to its starting closed position with a small internal torsion spring.

Nate is pictured here demonstrating the results of the new linkage. While baking cookies, he was able to have exact grip strength while holding a bottle still, carrying an egg without cracking or dropping it, Crushing a cup, and holding rounded objects without them being scissor pinched out of the "hand"

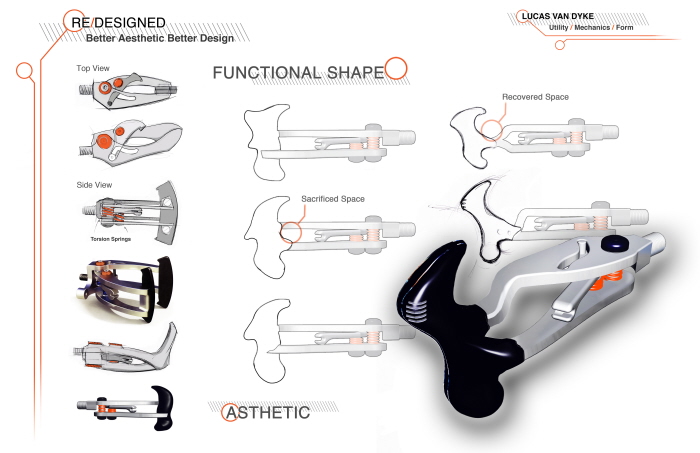

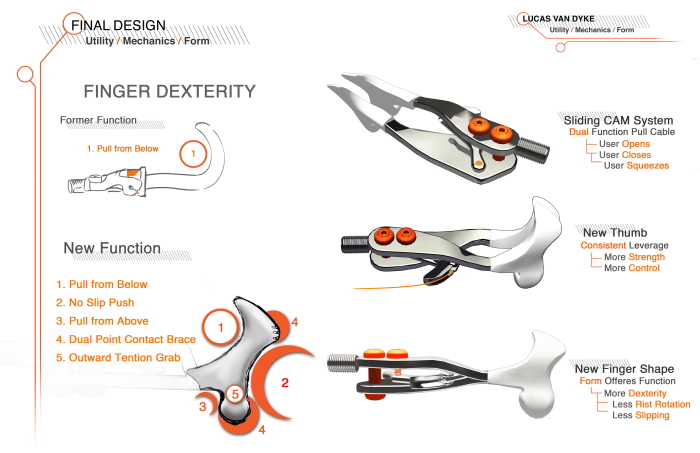

I then took the project a step further by redesigning the fingers of the prosthetic. The redesign of the fingers would allow greater functionality, and a reduction in both wasted space taken up by the mechanics, as well as in the amount of rotations of the mechanical wrist to accomplish tasks. The new finger shape deliver a variety of new functions. It will center itself when pressed against shopping cart handles and door nobs. It has two points of contact as to secure something from swiveling while pinned. It also can "hook" something using the bottom of the top of the fingers.

The new prosthetic is able to be inserted between things to apply an outward force. The Fingers are curved from top to bottom in a convex shape similar to this -> )) which helps it not catch on the users leg while walking. The convex curved shape also helps grip cylindrical objects like bottles or cans. The finger tips are thinner but deeper like paddles to increase effective gripping surface area and not have the prosthetic look like a sharp hook and have a rubberized covering which both help in not having it feel as cold to the touch. These improvements help so much including gentle tasks such as buttoning your child's pants or holding their hand while crossing the street.

With the refreshed design and new technology in this prosthetic, there is improved dexterity, increased strength, and more precise control. While the design for something of this nature is never complete, this design is an improvement from the basic mechanical hook while still using the most appropriate technology without relying on electrical or computerized components.

Jonathan Kuniholm reviewed our designs and gave positive feedback for the improvements.

Here is a link to Jon Kuniholm talking at UNC for a TEDx Talk: http://www.youtube.com/watch?v=7AWRSVuN2ik

And here is a link to Open Prosthetics.org which is a project started by Jon Kuniholm in the attempt to open source design developments in the realm of prosthetic: http://www.openprosthetics.org/

gLike