A group project to modify the most common Wine Corking device used at small wineries. Focus on Research and Ergonomics. Ended with a publish ready article and redesign recommendation to cut effort used in corking by over 75%, making it safe and comfortable.

Corking was found to be the most physically taxing, causing physical pain, and shoulder injury. Employees took turns sharing the task to help share the pain.

Through multiple online surveys and forums, corking was confirmed to be an overuse of the arm

Decided to modify the most common small winery corking device which due to the excessive force needed to operate was injuring users

Market analysis, product research, and patent search results.

Concept development including manual and powered corkers. But with the allure and romance surrounding the "hand made" bottle of wine, making the process machine based was not the answer. We needed to keep the process "by hand."

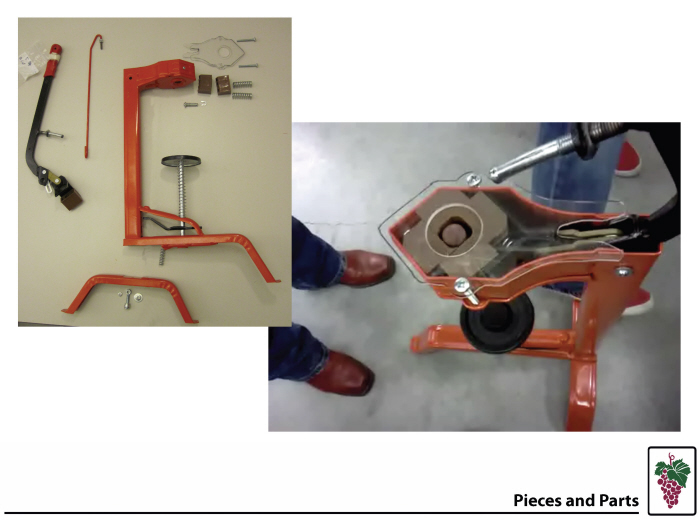

We bought a floor standing wine corker, and took it apart and put it back together. Exploration of how the device worked, and what could be changed. It was a very simple device so we focused on the handle for change.

Identified the muscles used in the corking process and hooked these muscles up to test what percent of their maximum ability they were using per pull.

Tested 6 handles variations, both 1 handed and 2 handed, at 4 differing lengths each to find which would be the least amount of muscle power used.

Using the same handle tester for all the pulls standardized the variations between individuals. So this eliminated the muscle differences between different people.

Different handles were attached and handle positions were changed measuring muscle use and comparing that use to maximum pull ability to get the percent of maximum used.

The results of the right arm muscles percent of maximum used with 24 unique handle positions. (The original handle is on the far left, note that it uses over 10% of maximum tricep ability to operate)

It is "scientifically safe" to do a repetitive motion if the muscles used are under 5% of maximum. An Orange line was drawn to erase all pulls that require above that barrier, then a green line was drawn to erase all handles which require over 2.5% of maximum muscle used. 1 handle variation survived the cut. (The original handle required 10% of max to operate.)

This handle variation took the muscle maximum used from 10% per pull with the original handle, to 2.5% used. // Handle Changes: The rotation of the rist is back to a natural body position, a longer lever arm to augment the applied force, and a double handle to allow for both arms to pull together or to take turns. Simple Change, Big Results

Took the redesign to the professionals to be tried out for feedback. Great responses to the redesign.

Simple attachment could be added to previously bought corkers, and a correction to the manufacturing of new corking machines would be simple. Attachments would be inexpensive, durable, and allow consumers to not replace their entire device.

With a consideration to ergonomics, this simple attachment would cut the effort originally required to use the corker by 75%, making it safe for repetitive use.

gLike