On pallets ready to be shipped out.

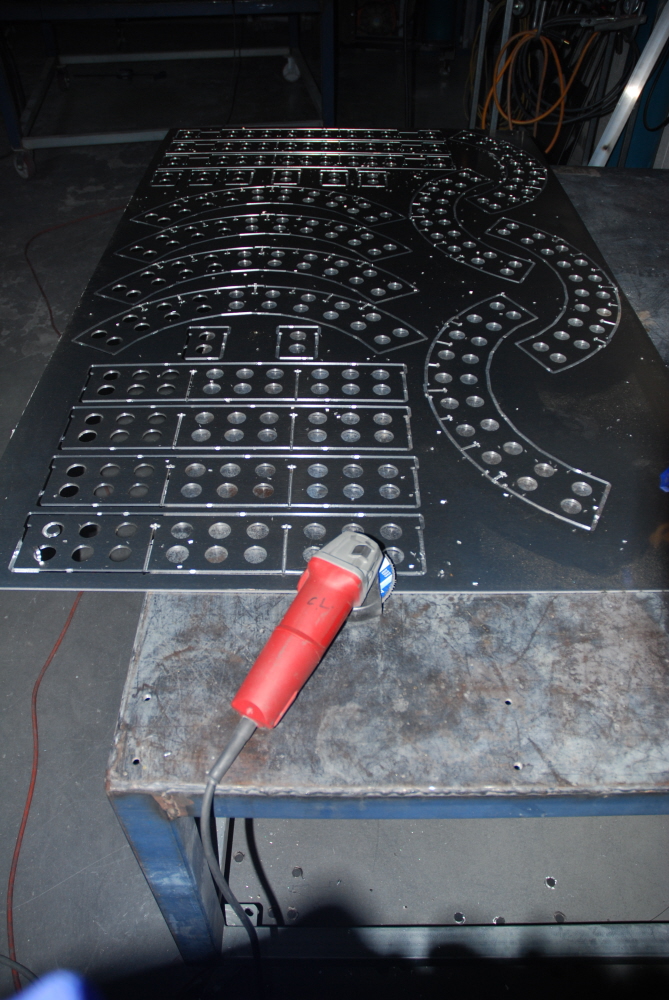

The parts are machined, but still need to be manually removed from plate material.

Here is my MDF assembly jig. Precise geometry makes assembling the clamshells quick and accurate.

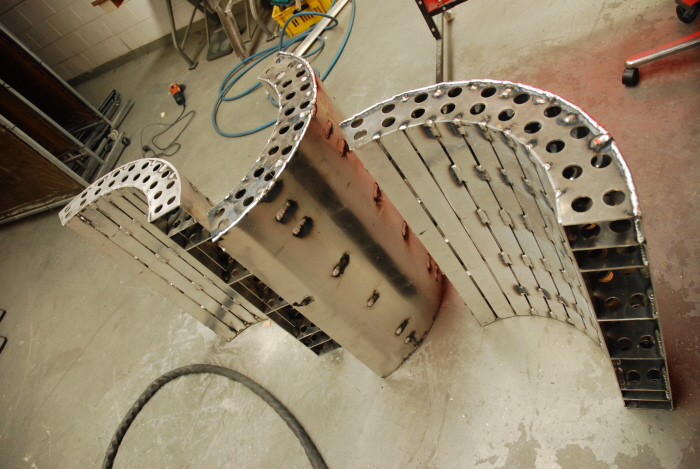

Clamshells welded and sanded.

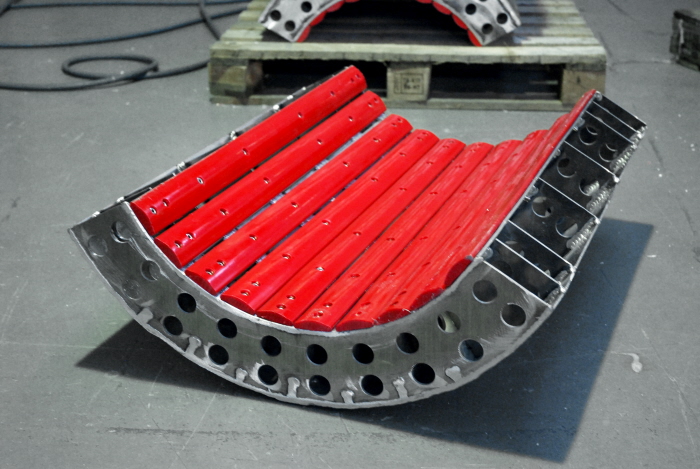

HDPE rubbing strip added.

Outer plates are 3mm aluminium.

Detail of structure.

Here you can see the pipes meeting. The clamshells are clamped either side of the join white the pipe ends are welded together.

gLike