Exocet: teaser - Teaser, more to come....

-Ideation sketches

-Clay modeling

-Prototype building

-etc.

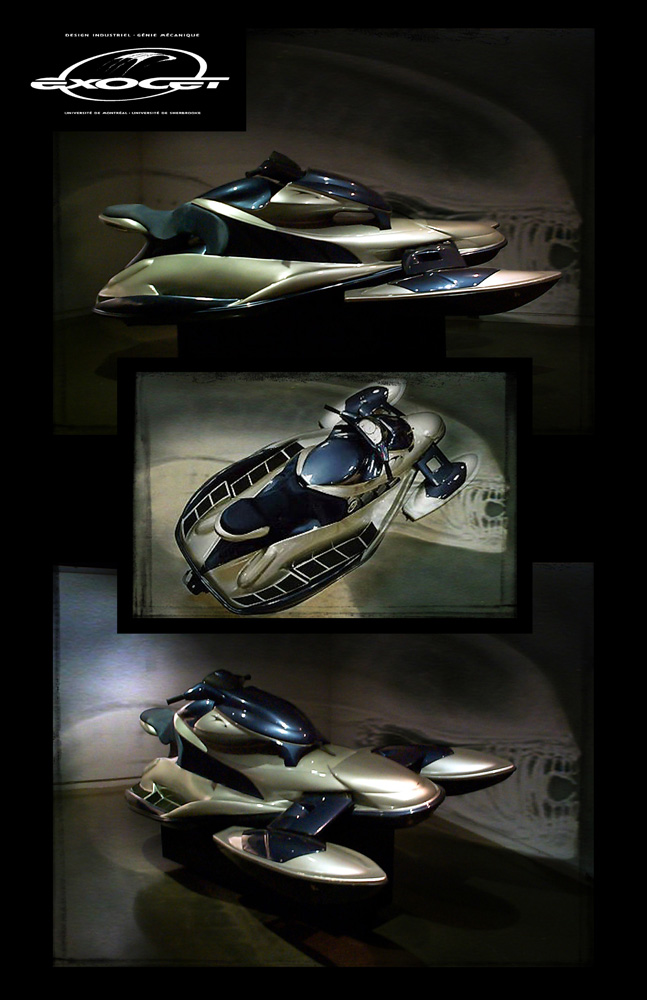

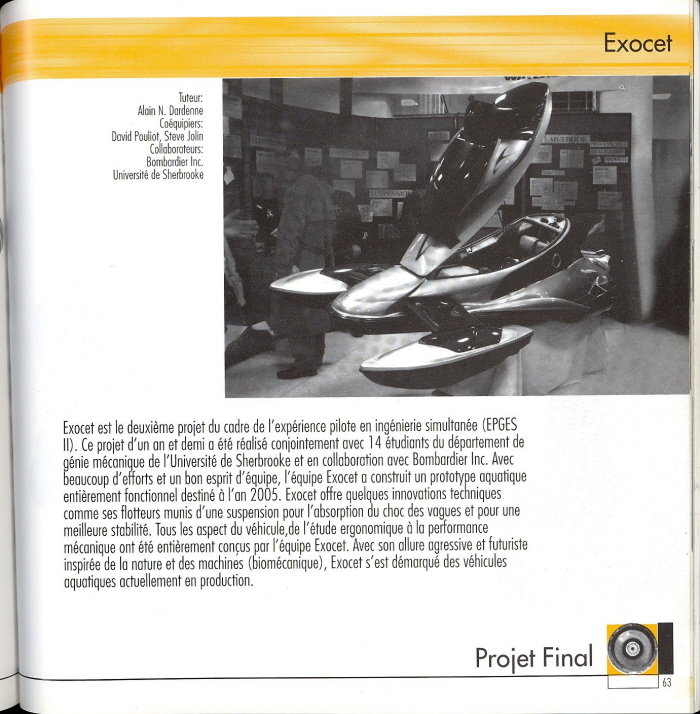

Exocet1: futuristic sea-doo (part1) - 1996-1997 school project. Sponsored by Bombardier. Collaboration between the University of Montreal (3 industrial design students) and the University of Sherbrooke (14 mechanical engineering students).

Goal: design and build a functional futuristic sea-doo prototype in one year.

Mule tesing video:

http://www.youtube.com/watch?v=L6_VU7-hSCU

Prototype tesing video:

http://www.youtube.com/watch?v=f3BF0QGfWhg

Exocet2: futuristic sea-doo - Other views

Exocet3: detail - Bodywork details

Exocet4: detail - Steering detailing

Exocet: phase1, theme and image boards - One of the first thing we did was study the market and imagined what kind of world 2007 would be.

-The first board shows a "waterworld"

-The second and third are the target market

Exocet: phase2, sketch1 - Early drawings.

- Sea-doo with some sort of a suspension

- Sea-doo inspired by the hydroplane boats

- Sea-doo inspired by the motorcylce

Exocet: phase2, sketch2 - Action scene

Exocet: phase3, sketch3 - Once the technical package and a overall look was determined, different concepts (details) were proposed.

Exocet: inspiration images - Here are some images that inspired the concept.

Exocet: phase4, model making - Once the concept drawing was chosen, a model was made with industrial clay.

-A line tape drawing was made with the mechanical package, this is for proportions and making sure the design fitted the mechanic (theorically).

-Ergonomic study was made since there was no such document availabe.

-Model base with mechanical package

-Model completed (it took two takes)

Exocet: prototype1 - This was built by the engineering group to validate the mechanical aspect.

Exocet: phase5, building showroom prototype - -The model was scanned. Over 100 sections were made.

-The sections were printed and clued on foam. The foam were clued together. This is the master for the fiberglass application.

-Car putty and fiberglass was used to make the details

-Fiberglass was shot on the master and once dried, the foam was removed from under.

Exocet team - Top image: the three industrial designer students

-Steve Jolin, David Pouliot & Trong-Kim Nguyen

Bottom image: the engineering students and design team

gLike