https://vimeo.com/390278384

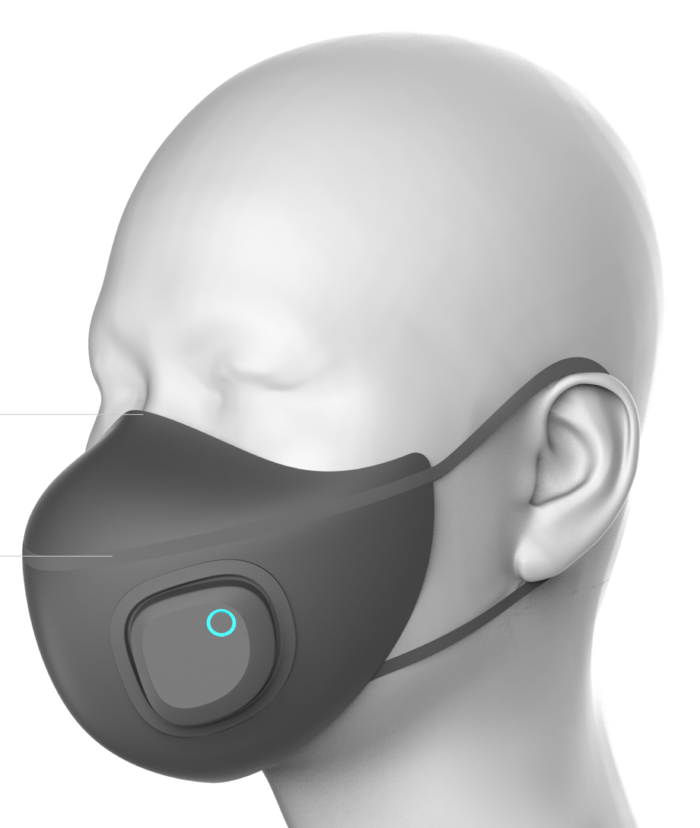

Early biometric 3D study

Early biometric 3D study

Early strap angle study

Patterning in paper-

Digital patterning

Early maquette for pattern development.

Stitched samples-

Vacuum forming composite layups with breathable Bemis PU Hotmelt film.

Vacuum forming composite layups with breathable Bemis PU Hotmelt film.

Cutting Vacuum formed composite layups out.

Hot air tape construction trials-

Hot air tape construction trials-

Exploration into composite layups with stiff non-woven composite which are cut for breathability..

Compression inmolding fabric. Mold has ability to cycle both hot and cold.

Compression molded trials.

Compression multiple trials failure due to over melt.

First batch of engineering samples for fit-

Exploration of Velcro and adjustment systems-

Laser cutting hole for fan-

Exploration of Velcro and adjustment systems-

Laser cut edge stabilized with TPU film.

Fit trials for lasered parts-

Compression molded knit parts- determining optimum knits for breathability.

Final assembly trials with early fan parts-

Compression multiple trials failure due to over melt.

Revised 3-D based on 2D patterning-

Compression molded fabric exploration-

Compression molded fabric exploration-

The beautiful mold with holding pins!

View of the compression mold parts!

Knitting final custom fabric with proprietary mix of heat activated yarns-

Knitting final custom fabric with proprietary mix of heat activated yarns-

Laser cut jig.

gLike