HIN Chicago

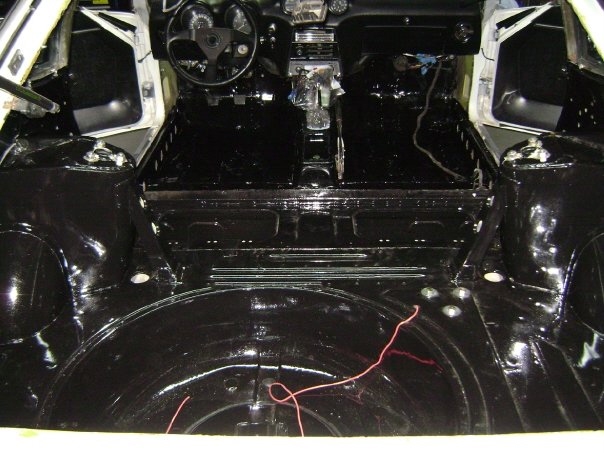

The interior of the uni-body was completely stripped by hand using hand scarper, and drill w/ wire brush attachment. I found some rust, hack-repairs, and 2 pennies

Went full OCD and masked off before applying the seam sealer

Applied 3M seam sealer to all floor pan seams

Full interior of uni-body with 2 coats of POR-15. Herculiner was later applied for sound deadening and protective purposes

Full interior of uni-body with 2 coats of POR-15. Herculiner was later applied for sound deadening and protective purposes

37 year old seat foam vs. new foam. There was a shopping bag around the headrest portion and a few random hack foam fixes, along with a bunch of horsehair and it smelled like Goodwill

completed interior

completed interior

drove for 2 weeks like this till my fenders came back from paint

dropped rear end

Shot of the underbody after the fuel tank was removed. Overall, pretty good condition with only mild surface rust

after hours of body work fuel tank

R200 diff when received. A hot mess.....rusted, bad seals, bad u-joints, bad bearings, ripped boots, but the gears were good

R200 diff rebuilt after hours of work. Blasted and repainted, powder coated rear cover, new studs, new hardware, new breather, new u joints, new boots, new bearings, and new gaskets

Billet aluminum rear diff mount and control arm rear mounts, along with 4130 tubular rear control arms

Billet aluminum rear diff mount and control arm rear mounts, along with 4130 tubular rear control arms

rebuilt rears

engine, in

Stripped and jet-hot coated 6-1 header

Personally made and designed fuel rail for triple-carb set-up. Later to be chrome plated

Fuel rail shown mounted to manifold studs. With personally/ custom made braided fuel lines and Aeroquip fittings to clear throttle linkage

Oct. 09 issue of Super Street

Oct. 09 issue of Super Street

3rd ward Milwaukee

gLike